铝镍钴永磁铁

铝镍钴永磁铁

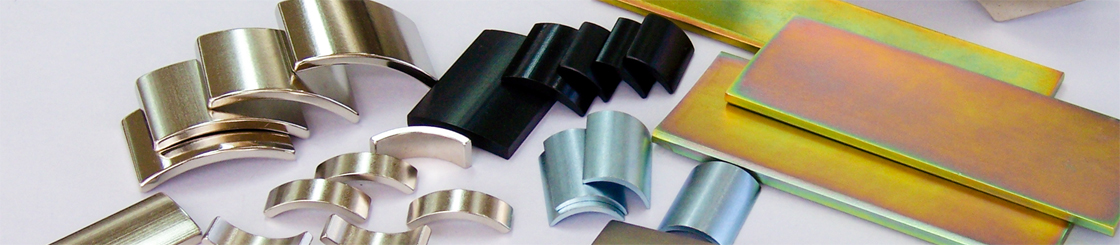

Alnico magnets are ideal for corrosive and high heat applications up to 930°F (500°C). Mag Spring can supply a variety of Cast and Sintered grades according to different application.

|

MaterialCode

|

Remanence

|

Coercivity

|

Intrinsic

Coercivity |

Max.EnergyProuct

|

Density

|

% ChangePer c

|

Tc

|

Remark

|

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Br

|

Hcb

|

Hcj

|

(BH)max

|

D

|

||||||||

|

mT

|

Gs

|

KA/m

|

Oe

|

KA/m

|

Oe

|

KJ/m3

|

MGOe

|

g/cm3

|

%K

|

℃

|

||

|

FLN8

|

520

|

5200

|

40

|

500

|

43

|

540

|

8-10

|

1.0-1.25

|

6.8

|

-0.022

|

760

|

Isotropic

|

|

FLNG12

|

700

|

7000

|

40

|

500

|

43

|

540

|

12-14

|

1.5-1.75

|

7.0

|

-0.014

|

810

|

|

|

FLNGT14

|

570

|

5700

|

76

|

950

|

78

|

980

|

14-16

|

1.75-2.0

|

7.1

|

-0.02

|

850

|

|

|

FLNGT18

|

560

|

5600

|

88

|

1100

|

90

|

1130

|

18-22

|

2.25-2.75

|

7.2

|

-0.02

|

850

|

|

|

FLNG28

|

1050

|

10500

|

46

|

580

|

47

|

590

|

28-33

|

3.5-4.15

|

7.2

|

-0.016

|

850

|

Anisotropic

|

|

FLNG34

|

1100

|

11000

|

50

|

630

|

51

|

640

|

34-38

|

4.3-4.8

|

7.2

|

-0.016

|

890

|

|

|

FLNGT28

|

1000

|

10000

|

56

|

700

|

57

|

710

|

28-30

|

3.5-3.8

|

7.2

|

-0.020

|

850

|

|

|

FLNGT31

|

780

|

7800

|

104

|

1300

|

106

|

1130

|

33-36

|

3.9-4.5

|

7.2

|

-0.020

|

850

|

|

|

FLNG33J

|

650

|

6500

|

136

|

1700

|

150

|

1880

|

31-36

|

4.15-4.5

|

7.2

|

-0.020

|

850

|

|

|

FLNGT38

|

800

|

8000

|

123

|

1550

|

126

|

1580

|

38-42

|

4.75-5.3

|

7.2

|

-0.020

|

850

|

|

|

FLNGT42

|

880

|

8800

|

120

|

1500

|

122

|

1530

|

42-48

|

5.3-6.0

|

7.25

|

-0.020

|

850

|

|

|

Material

Code

|

Remanence

|

Intrinsic

Coercivity

|

Max.Energy

Prouct

(BH)max

|

Density

D

|

Equivalent

MMPA

Class

|

% Change

Per c

|

Tc

|

Tw

|

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Br

|

Hcj

|

|||||||||||

|

mT

|

Gs

|

KA/m

|

Oe

|

KJ/m3

|

MGOe

|

g/cm3

|

Near Br

|

Near Hcj

|

℃

|

℃

|

||

|

*LN9

|

680

|

6800

|

30

|

380

|

9.0

|

1.13

|

6.9

|

Alnico3

|

-0.03

|

-0.02

|

810

|

450

|

|

*LN10

|

600

|

6000

|

40

|

500

|

10.0

|

1.20

|

6.9

|

-0.03

|

-0.02

|

810

|

450

|

|

|

*LNG12

|

720

|

7200

|

45

|

500

|

12.4

|

1.55

|

7.0

|

Alnico2

|

-0.03

|

-0.02

|

810

|

450

|

|

*LNG13

|

700

|

7000

|

48

|

600

|

12.8

|

1.60

|

7.0

|

|||||

|

LNG37

|

1200

|

13000

|

48

|

600

|

37.0

|

4.65

|

7.3

|

Alnico5

|

-0.02

|

0.02

|

860

|

525

|

|

LNG40

|

1250

|

12500

|

48

|

600

|

40.0

|

5.00

|

7.3

|

|||||

|

LNG44

|

1250

|

12500

|

52

|

650

|

44.0

|

5.50

|

7.3

|

|||||

|

LNG52

|

1300

|

13000

|

56

|

700

|

52.0

|

6.50

|

7.3

|

Alnico5DG

|

||||

|

LNG60

|

1350

|

13500

|

59

|

740

|

60.0

|

7.50

|

7.3

|

Alnico5-7

|

||||

|

LNGT28

|

1000

|

10000

|

58

|

720

|

28.0

|

3.50

|

7.3

|

Alnico6

|

-0.02

|

0.03

|

860

|

525

|

|

LNGT36J

|

700

|

7000

|

140

|

1750

|

36.0

|

4.50

|

7.3

|

Alnico8HC

|

-0.025

|

0.02

|

860

|

550

|

|

*LNGT18

|

580

|

5800

|

100

|

1250

|

18.0

|

2.20

|

7.3

|

Alnico8

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT32

|

800

|

8000

|

100

|

1250

|

32.0

|

4.00

|

7.3

|

Alnico8

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT40

|

800

|

8000

|

110

|

1380

|

40.0

|

5.00

|

7.3

|

|||||

|

LNGT60

|

900

|

9000

|

110

|

1380

|

60.0

|

7.50

|

7.3

|

Alnico9

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT72

|

1050

|

10500

|

112

|

1400

|

72.0

|

9.00

|

7.3

|

|||||

Alnico Magnets